3D CAD Software

22-Nov-2017

Best 3D CAD Software

3D CAD Software, we have some conversation about when the CAD Software has started its journey. Beginning in the 1980s, computer-aided design programs reduced the necessity for draftsmen, particularly with little to mid-sized corporations. Their affordability and skill to run on personal computers additionally allowed engineers to try and do their own drafting work, eliminating the necessity for entire departments. In today’s world, several students in universities don’t learn manual drafting techniques as a result of they’re not needed to try and do so. The times of hand drawing for final drawings are about over.

3D CAD Software:

Universities do not need the employment of protractors and compasses to make drawings. Instead, there are several categories that specialize in the employment of CAD (Computer-Aided Design) software. CAD design software is employed in every trade together with the creation of landscape designs, bridges, workplace buildings, and picture show (movies) animation.

CAD has evolved to incorporate the assembly of two-dimensional (2D) drawings and three-dimensional (3D) virtual models of real or imaginary objects. CAD, additionally referred to as a package of designing and drafting (CADD), is the use of engineering for the process of style and design documentation.

8 Criteria for Choosing 3D CAD Software:

1.Efficiency:

When evaluating 3D CAD software, conclude how affordable each package is at making the kinds of products your company designs. If your company designs a modern product, explore the tools for making free-form surfaces and blends with continuous curvature.

Designers of machinery should examine how easily they can assemble large numbers of components and insert purchased components, like fasteners and electrical parts, from a library. The 3D CAD software that combines exceptional technical capabilities with affordable ownership costs offers significant price advantages.

2.Having Drafting Tools for Today and the Future:

Any 3D CAD software you buy will create drawings of your current standards for dimensions, tolerances, lettering, and element lists. Be sure that your drawings can be exported in standard formats like PDF, DXF, and DWG. Model-based definitions allow automated manufacturing and inspection systems to read measurements and tolerances from 3D models, saving time in drafting, product data management (PDM), and defect reduction.

3.Taking Design from Concept Level through Manufacturing:

Search for 3D CAD software with a wide range of applications that reduce not only design time but also testing, machining, value estimating, and inspection. Such tools can be especially beneficial for companies that design products based on customer specifications, like configuration software for molding assemblies and stamping dies.

3D CAD Software and Simulations:

To reduce the need for physical exams, look for CAD systems that integrate analytical tools or efficient interfaces with preferred simulation software. These tools can help test kinematics, dynamics, pressure, deflection, vibration, temperatures, and fluid flow, reducing the time needed to get products to market.

4.Managing Data Well:

Organizations with multiple designers benefit from PDM systems integrated with their CAD tools. PDM ensures that files are stored and organized automatically, preventing errors like sending the wrong revision to manufacturers. It also facilitates finding existing elements to reuse instead of reinventing them.

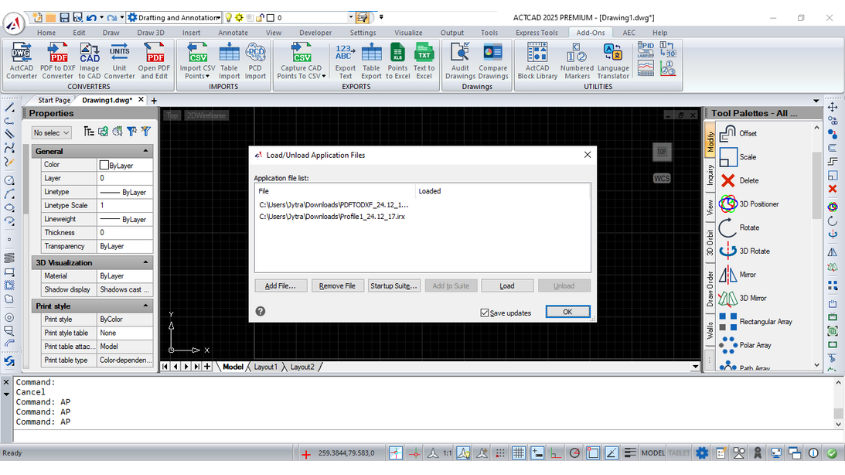

ACTCAD:

ACTCAD is a CAD software that helps eliminate costly errors and wasted hours by organizing files and generating materials lists for cost estimating. Its advanced PDM system automates change-control processes, ensuring that outdated information isn’t sent to factories or suppliers.

5.Evaluating Computing Technology:

It’s essential to select a CAD vendor that adapts to evolving technology to avoid managing a costly CAD system in the future. Consider vendors with strong R&D teams and look for floating licenses that allow designers to share resources without hassle.

6.Having a Short Learning Curve:

3D CAD techniques require training and experience. Choose a system that is easy to learn and has a consistent user interface. Additionally, training materials should be available to help reduce development costs. Opt for systems with built-in tutorials, computer-based learning aids, and responsive online communities for support.

7.One Size Does Not Fit All:

The standards listed here may not apply to every organization. It’s essential to have deep knowledge of your company’s engineering needs before selecting a CAD software. Make sure to evaluate at least three vendors to avoid making decisions based on brand preference or limited criteria.

8.Buy from a Helpful Dealer:

A successful relationship with your CAD software dealer starts with the purchase. Choose a dealer with the expertise to assist you with integrating 3D design into your production process. Additionally, ensure they offer quality training and support to improve your design and manufacturing processes.

Conclusion:

Choosing the right 3D CAD software can save you time and money. Select software based on your company’s specific needs, rather than making decisions based on promotions or brand names. A thoughtful decision can significantly enhance your company's profits. Be sure to choose carefully when investing in CAD software.

About this blog

We frequently publish blog articles about ACTCAD software in terms of new features, improvements, releases, special offers, technical articles etc. Please subscribe to our newsletter to get regular updates.

Search Blog

Random Posts